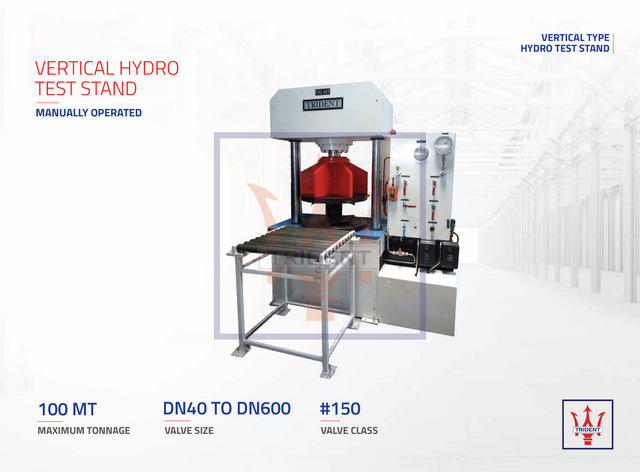

Vertical Test Stand (VTS)

Its vertical design ensures even pressure distribution and is space-efficient, making it ideal for facilities with limited space.

Overview

Product Range

Key Features:

Vertical Orientation: Designed to hold components upright, which is ideal for items like cylinders, valves, and smaller tubular sections. The vertical positioning is beneficial for space-saving and ensures even pressure distribution.

Pressure System: Equipped with a high-pressure water pump to pressurize the item being tested. The water is pumped into the component, and pressure is increased to a specific level for the test.

Monitoring Equipment: Includes pressure gauges, digital displays, and sensors to monitor the internal pressure levels, allowing operators to observe test parameters in real time.

Leak Detection: The system is designed to detect and monitor any leaks or weaknesses in the tested component, ensuring that it meets safety and performance standards.

Safety Features: Integrated safety mechanisms, such as pressure relief valves and emergency shut-off switches, protect the operators and equipment from high-pressure failures.

Control Panel: Operators can manage the pressure levels, monitor the duration of the test, and ensure the testing process is compliant with the required standards using the control system.

Water Drainage System: After the test is complete, water is safely drained from the component using the built-in drainage system.

Safety Valve Vertical Test Bench Manufacturer in India

Key Features of Our Safety Valve Test Bench

- High-Pressure Testing - Capable of handling up to 690 BAR pressure.

- Precise control of pressure and flow - ensuring accurate results.

- Versatile Valve Testing - Supports multiple valve types and sizes.

- Hydraulic Clamping System - Ensures firm and secure testing conditions.

- Automated Test Control - Advanced software for real-time monitoring and data logging.

- Leak Detection Technology - Enhances safety and accuracy.

- Customizable Design - Tailored solutions to meet specific industrial needs.

Frequently Asked Questions (FAQs)

1. What is a safety valve test bench?

2. What types of valves can be tested on this machine?

Our vertical test bench is suitable for testing:

- Set Pressure Relief Test

- Seat Test

- Re-Seat Pressure test

- Blowdown test

- Pop-up test

- Full Lift Test

3. What is the maximum pressure capacity of the test bench?

4. What industries require safety valve testing?

5. How does the hydraulic system improve testing accuracy?

6. Can the test bench be customized for specific valve sizes?

7. Does the machine have data logging and reporting features?

8. What safety features are included in the test bench?

- Leak detection sensors

- Overpressure protection

- Automated emergency shutdown

- High-pressure safety mechanisms

- Advanced hydraulic clamping systems

- Safety Guards with pressure interlocking to ensure operator safety

9. Is the test bench suitable for large industrial valves?

10. How can I purchase a safety valve test bench?

- To book a free consultation, please contact us on our below mail id:

Why Choose Trident Hydro Solutions?

- Top Safety Valve Test Bench Manufacturer in India

- Reliable & Customizable Testing Solutions

- Industry-Leading Performance & Durability in valve test bench

- Trusted by Leading Industries Worldwide

- High-Precision Hydraulic Technology

- Strong service teams

- For more details or to request a quote, contact Trident Hydro Solutions today!